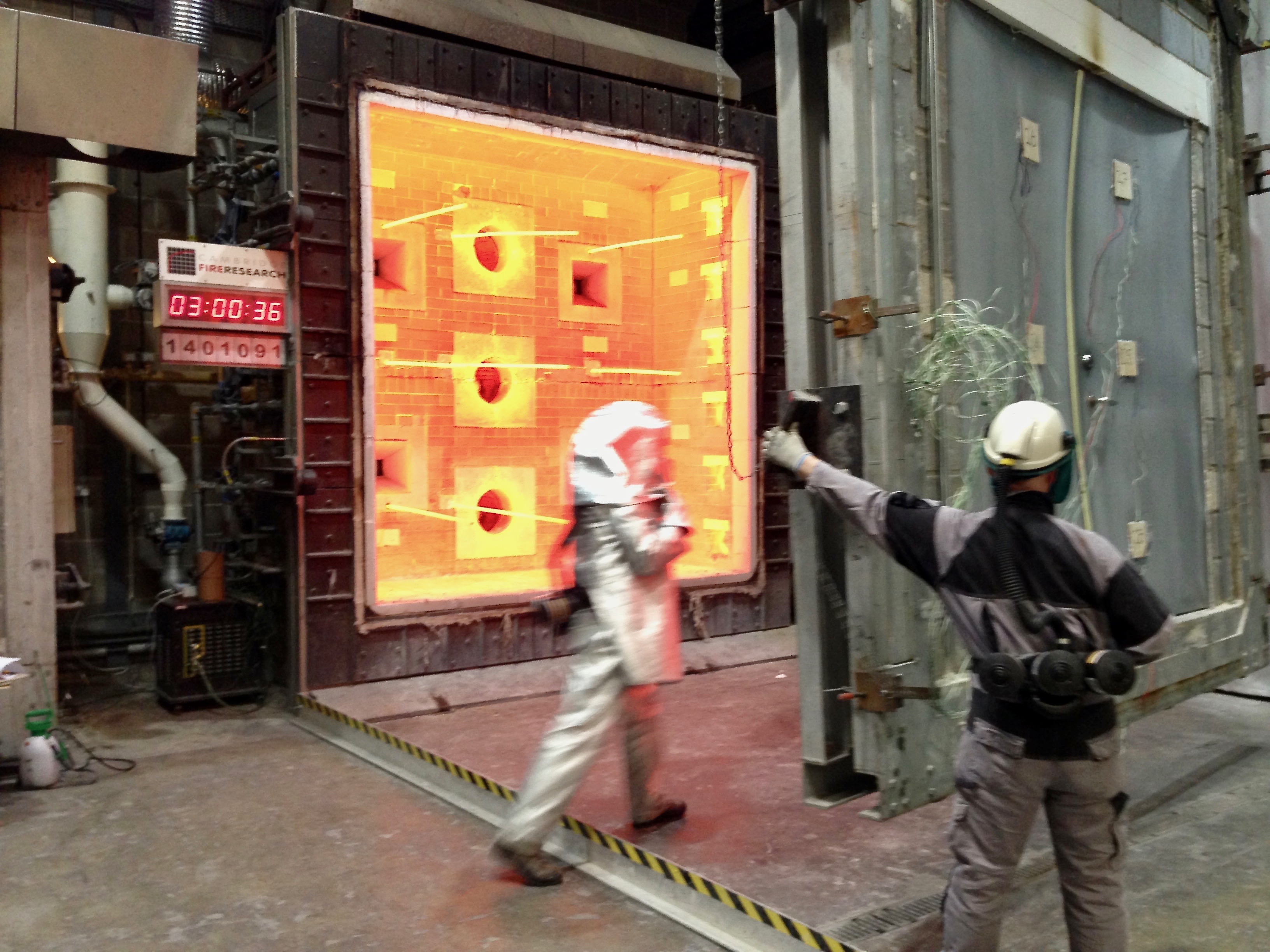

Fire Standards

UL 10C Positive Fire Pressure Tests of Door Assemblies

EN 1634-1 Fire resistance and smoke control tests for door and shutter assemblies, openable windows and elements of building hardware

BS 476/Part 22 Fire tests on building materials and structures

EN 1363-1 & 1364-1 Fire resistance tests for non-load-bearing elements – Walls

Latest News

Split Height Transaction Window Duo

Using experience on previous projects and customers requirements we have designed a split height transaction window offering standing and DDA access to reception and data centre environments.

For more information and pricing please contact our office on info@architecturalarmour.com or +44(0)1981 257000

Read more

Increased Stock for Express Delivery

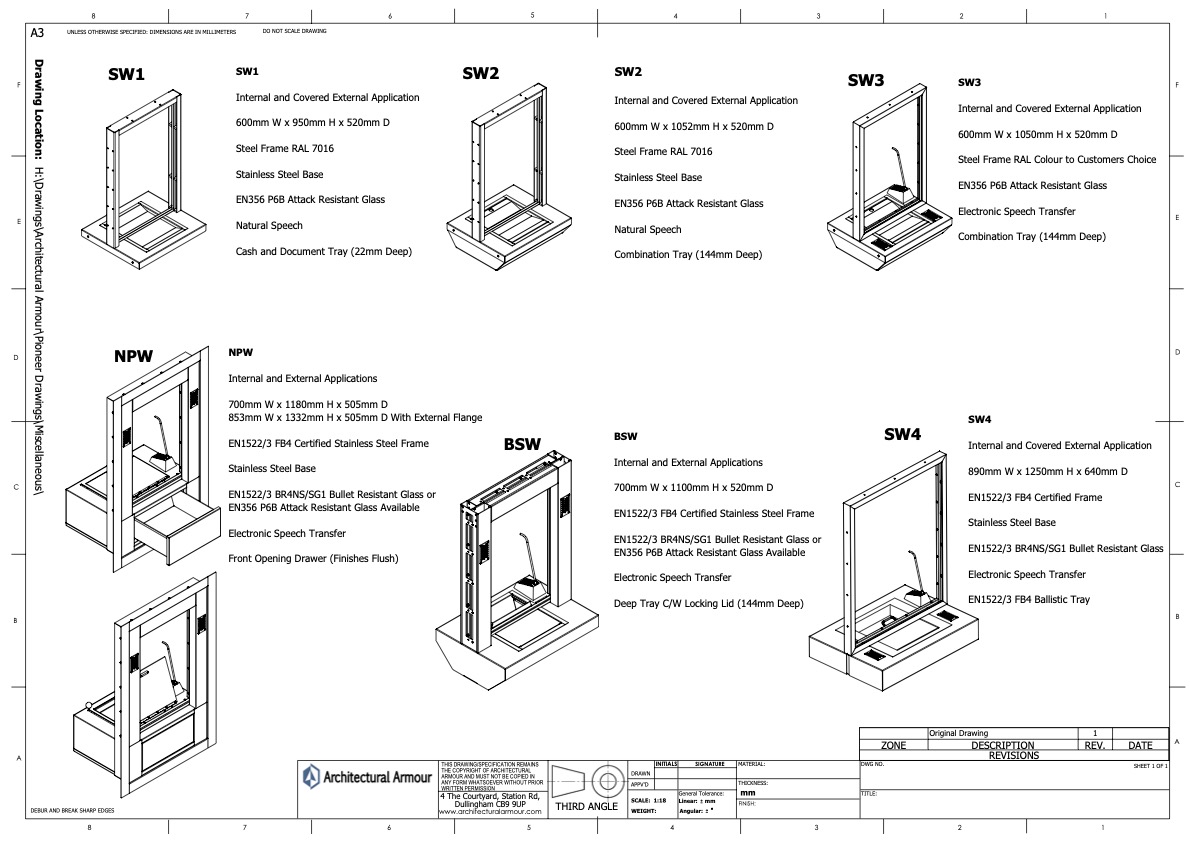

We have increased our range of stock transaction windows to six units , ready for express dispatch.

Our range of transaction windows include, physical attack resistant and bullet resistant internal and external models. Please see below an outline of our products.

Architectural Armour are offering standard stock items and bespoke orders to suit. Please contact us on +44(0) 1981 257000

Read more