ISO 16933:2007 Arena Testing

ISO 16933:2007 Arena Testing

GLASS IN BUILDING -- EXPLOSION-RESISTANT SECURITY GLAZING -- TEST AND CLASSIFICATION FOR ARENA AIR-BLAST LOADING

ISO 16933:2006 provides a structured procedure to determine the air-blast resistance of glazing and sets forth the required apparatus, procedures, specimens, other requirements and guidelines for conducting arena air-blast tests of security glazing. Seven standard blasts simulating vehicle bombs and seven standard blasts simulating smaller satchel bombs that can be used to classify glazing performance are incorporated in this International Standard and cover a broad range of blast parameters.

To view products that can offer blast resistant properties, see the below links.

Stock items

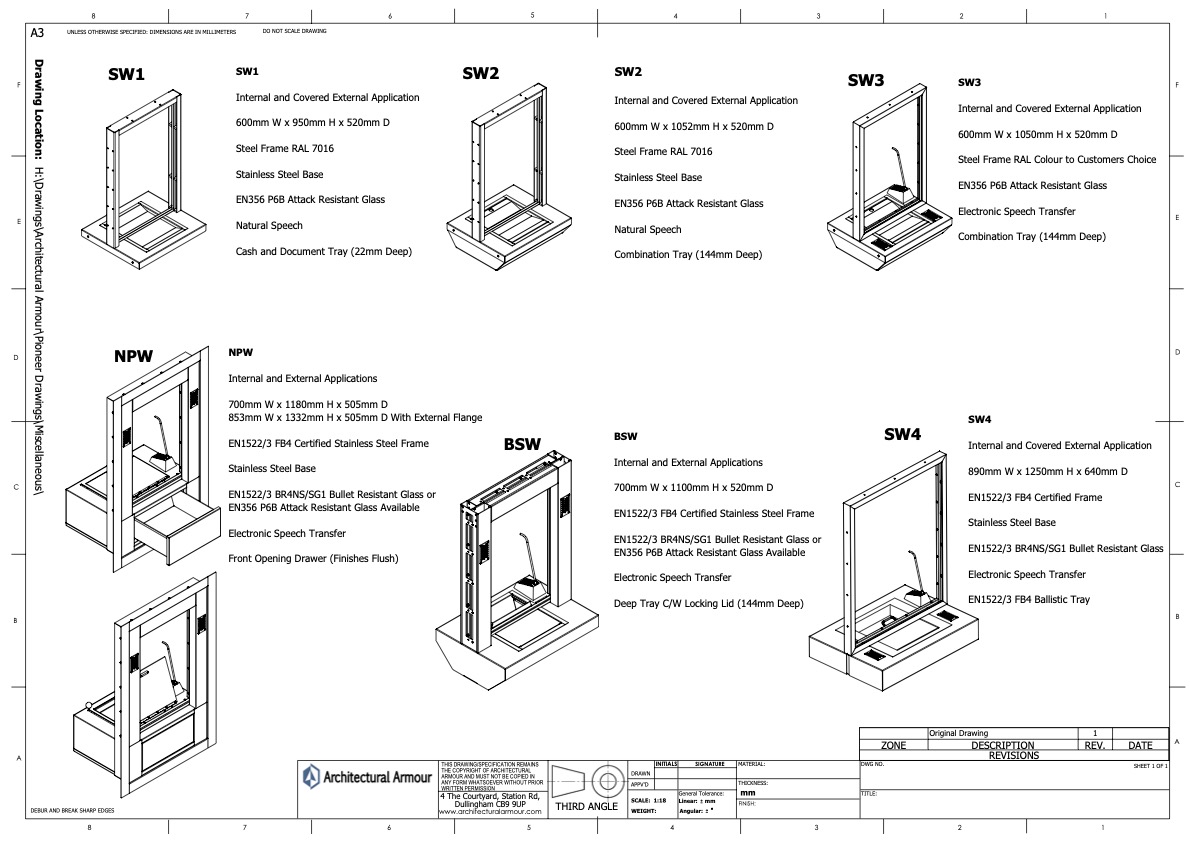

Bullet Resistant Transaction Window - Exterior / Interior Bullet Resistant Window with Electronic Speech, Ticket Window.

Night Pay Window / Hatch - A flat fronted Transaction Window with opening drawer, typically uses Petrol Stations and Pharmacies.

BR6 Guard House Transaction Window -Flat fronted Ballistic Window with opening drawer for document transfer.

All of the above can also be manufactured in bespoke sizes.

Bespoke items

Blast Resistant Glass -Laminated Blast resistant Glass to incorporate into Blast Windows and Doors

Blast Windows - Blast windows to protect against terrorist attacks and longer petrochemical explosions

Security Counters and Screens - Physical, Ballistic or Blast resisting counters for any application to keep staff secure.

Ballistic and Blast Resistant Guard Houses - Modular New Build or Upgrading existing. EN1522/3 FB2 to FB7, NIJ 0108.01 LII to IV UL 752.

Explosion Vents and Rupture Panels - Safety devices used to contain an explosive blast effect within a building.

Blast Resistant Doors - Steel manufactured doors offering blast protection to buildings

Security glazing, including that fabricated from glass, plastic glazing sheet material, glass-clad plastics, laminated glass, insulated glass, glass/plastic glazing materials and film-backed glass, can be tested and classified in a standard frame or tested but not classified in frames provided with the glazing.

Classification and ratings are assigned based on the performance of glazing loaded by air-blast pressures and impulses and are specific to the blast characteristics under which the test takes place. Glazing that has received an air-blast classification and rating is suitable for use in blast-resistant applications only for blasts of comparable characteristics and only if installed in a properly designed frame. Design based on knowledge of the air-blast resistance reduces the risk of personal injury.

| Classification Code (a) | Mean peak air-blast pressure (kPa) | Mean positive phase impulse (kPa-ms) |

| EXV45 (X) | 30 | 180 |

| EXV33 (X) | 50 | 250 |

| EXV25 (X) | 80 | 380 |

| EXV19 (X) | 140 | 600 |

| EXV15 (X) | 250 | 850 |

| EXV12 (X) | 450 | 1200 |

| EXV10 (X) | 800 | 1600 |

(a) In the classification code, the letters, i.e. EXV refer to the type, i.e. a vehicle bomb; numbers denote a nominal standoff distance, expressed in meters, when a charge of 100kg TNT equivalent is placed at a point perpendicular to the surface of the test specimen when mounted in a reaction structure (test cubicle) of face size abut 3 x 3 m and (X) denotes the hazard rating received during the test. For example, classification code EXV25 (C) applies to a test in which a standard blast having peak air-blast pressure of 80kPa and positive phase impulse of 380 kPa-ms, resulting in damage to the glazing resulting in hazard rating C.

Nominal charge sizes and standoff distances for typical test frames compared to those normal to a large facade calculated to equate to the blast values for the vehicle-bomb classifications (ISO 16933:2007).

| Classification criteria blast values (a) | Nominal standoffs (b) of approx. 100kg TNT for a small test frame | Calculated nominal equivalents (c) to a large facade | |||

| Classification Code | Pressure (kPa) | Impulse (kPa-ms) | TNT equivalent size (kg) | Standoff distance (m) | |

| EXV45 (X) | 30 | 180 | 45 | 30 | 32 |

| EXV33 (X) | 50 | 250 | 33 | 30 | 23 |

| EXV25 (X) | 80 | 380 | 25 | 40 | 19 |

| EXV19 (X) | 140 | 600 | 19 | 64 | 17 |

| EXV15 (X) | 250 | 850 | 15 | 80 | 14.4 |

| EXV12 (X) | 450 | 1200 | 12 | 100 | 12.4 |

| EXV10 (X) | 800 | 1600 | 10 | 125 | 11 |

(b) Derived from test measurements of reflected blast values on the face of vertical 3.15 × 3.15 m test frames

positioned at standoffs from 100 kg TNT equivalent charges placed 1.2 m above a hard surface to exceed the

classification criteria.

(c) Calculated assuming hemispherical surface bursts on the ground at standoffs normal to the vertical face of

large facades.

Classification criteria for hand-carried satchel bombs (ISO 16933:2007).

| Classification Code (a) | Mean peak air-blast pressure (kPa) | Mean positive phase impulse (kPa-ms) |

| SB1 (X) | 70 | 150 |

| SB2 (X) | 110 | 200 |

| SB3 (X) | 250 | 300 |

| SB4 (X) | 800 | 500 |

| SB5 (X) | 700 | 700 |

| SB6 (X) | 1600 | 1000 |

| SB7 (X) | 2800 | 1500 |

(a) In the classification code the letters, i.e. ‘SB’, refer to the type, i.e. a hand-carried satchel bomb, the number designates the standard blast and (X) denotes the hazard rating received during the test. For example, classification SB4(C) applies to a test in which a standard blast having peak air-blast pressure of 800 kPa and positive phase impulse of 500 kPa- ms resulted in damage to the glazing resulting in hazard rating C.

Nominal charge sizes and standoff distances for typical test frames compared to those normal to a large facade calculated to equate to the blast values for the satchel bomb classifications (ISO 16933:2007).

| Classification criteria blast values (a) | Nominal standoffs (b) of approx. 100kg TNT for a small test frame | Calculated nominal equivalent (c) to a large facade | ||||

| Classification Code | Pressure (kPa) | Impulse (kPa-ms) | TNT equivalent charge size (kg) | Standoff distance (m) | TNT equivalent charge size (kg) | Standoff distance (m) |

| SB1 (X) | 70 | 150 | 3 | 9 | 3.25 | 9.00 |

| SB2 (X) | 110 | 200 | 3 | 7 | 3.50 | 7.26 |

| SB3 (X) | 250 | 300 | 3 | 5 | 3.50 | 5.07 |

| SB4 (X) | 800 | 500 | 3 | 3 | 3.70 | 3.40 |

| SB5 (X) | 700 | 700 | 12 | 5.5 | 12.00 | 5.26 |

| SB6 (X) | 1600 | 1000 | 12 | 4 | 12.60 | 4.06 |

| SB7(X) | 2800 | 1500 | 20 | 4 | 21.00 | 4.00 |

(a) See Table 11.

(b) Derived from test measurements of reflected blast values on the face of vertical 2.4 × 2.4 m test frames

positioned at the standoffs listed from charges of TNT equivalent mass listed to exceed the classification

criteria. The charges were positioned at the distances above the hard surfaces as defined above.

(c) Calculated assuming hemispherical surface bursts on the ground at standoffs normal to the vertical face of

large facades.

|

Hazard rating |

Hazard-rating description |

Definition |

|

A |

No break |

The glazing is observed not to fracture and there is no visible damage to the glazing system. |

|

B |

No hazard |

The glazing is observed to fracture but the inner, rear face leaf is fully retained in the facility test frame or glazing system frame with no breach and no material is lost from the interior surface. Outer leaves from the attack face may be sacrificed and may fall or be projected out. |

|

C |

Minimal hazard |

The glazing is observed to fracture. Outer leaves from the attack face may be sacrificed and may fall or be projected out. The inner, rear face leaf shall be substantially retained, with the total length of tears plus the total length of pullout from the edge of the frame less than 50 % of the glazing sight perimeter. Also, there are no more than three rateable perforations or indents anywhere in the witness panel and any fragments on the floor between 1 m and 3 m from the interior face of the specimen have a sum total united dimension of 250 mm or less. Glazing dust and slivers are not accounted for in the hazard rating. If by design intent there is more than 50 % pullout but the glazing remains firmly anchored by purpose-designed fittings, a rating of C (minimal hazard) may be awarded, provided that the other fragment limitations are met. The survival condition and anchoring provisions shall be described in the test report. |

|

D |

Very low hazard |

The glazing is observed to fracture and significant parts are located no further than 1 m behind the original location of the rear face. Parts be projected any distance from the attack face towards the blast source. Also, there are no more than three rateable perforations or indents anywhere in the witness panel, and any fragments on the floor between 1 m and 3 m from the interior face of the specimen have a sum total united dimension of 250 mm or less. Glazing dust and slivers are not accounted for in the rating. |

|

E |

Low hazard |

The glazing is observed to fracture, and glazing fragments or the whole of the glazing fall between 1 m and 3 m behind the interior face of the specimen and not more than 0.5 m above the floor at the vertical witness panel. Also, there are 10 or fewer rateable perforations in the area of the vertical witness panel higher than 0.5 m above the floor and none of the perforations penetrate more than 12 mm. |

|

F |

High hazard |

Glazing is observed to fracture and there are more than 10 rateable perforations in the area of the vertical witness panel higher than 0.5 m above the floor, or there are one or more perforations in the same witness panel area with fragment penetration more than 12 mm. |

For our full range of technical specifications please click on relevant headings below;

Other Blast Specifications

GSA-TS01:2003 Standard Test Method for Glazing and Window Systems Subject to Dynamic Overpressure Loadings

EN 13541 Glass in building - Security glazing - Testing and classification of resistance against explosion pressure

EN 13123-2 Windows, doors and shutters - Explosion resistance - Requirements and classification

Fire Specifications

UL 10C Positive Fire Pressure Tests of Door Assemblies

EN 1363-1 Fire resistance tests –Part 1: General Requirements

EN 1364-1 Fire resistance tests for non-load-bearing elements – Part 1: Walls

BS 476 Part 22 Fire tests on building materials and structures

EN 1634-1 Fire resistance and smoke control tests for door and shutter assemblies, openable windows and elements of building hardware

Attack Specifications

EN 1627 Pedestrian door-sets, windows, curtain walling, grilles and shutters - Burglar resistance - Requirements and classification

LPS 1270 Requirements & testing procedures for the LPCB approval & Listing of intruder resistant security glazing unit

LPS 1175 Requirements and testing procedures for the LPCB certification and listing of intruder resistant building components, strongpoints, security enclosures and free-standing barriers

EN 356 Glass in building - Security glazing - Testing and classification of resistance against manual attack.

Ballistic Specifications and Standards

EN 1063 Glass in Building - Security Glazing - Testing and Classification of Resistance Against Bullet Attack

UL 752 Standard for Bullet-Resisting Equipment

BS 5051 Bullet-resistant glazing - Part 1: for interior use- Part 2: for Exterior use

NIJ 0108.01 US National Institute of Justice Standard-Test and Certification for Ballistic Resistant Materials

EN 1522/3 Windows, doors, shutters and blinds - Bullet resistance - Requirements and classification / Test method

This is an extract not a full report and Architectural Armour Ltd accepts no liability for any loss, direct, indirect or consequential damage incurred by using this information, to the fullest extent permitted by law. You should make your own judgement as regards use of this document and seek out the full test standards.

Latest News

Split Height Transaction Window Duo

Using experience on previous projects and customers requirements we have designed a split height transaction window offering standing and DDA access to reception and data centre environments.

For more information and pricing please contact our office on info@architecturalarmour.com or +44(0)1981 257000

Read more

Increased Stock for Express Delivery

We have increased our range of stock transaction windows to six units , ready for express dispatch.

Our range of transaction windows include, physical attack resistant and bullet resistant internal and external models. Please see below an outline of our products.

Architectural Armour are offering standard stock items and bespoke orders to suit. Please contact us on +44(0) 1981 257000

Read more